Whether it is a water protection leak that causes the laser power supply to short circuit (such as the JGHY12570 water protection position is installed on the side, which is just above the laser power supply), whether 107 water pump is short, and the indoor open circuit is too small. If so, please check the main contactor and control transformer. The machine fails to start and trips in the open circuit of the roomĬheck whether the emergency stop pops up, whether the external circuit is connected, and whether the internal circuit breaker is closed.ĭo you hear a crackling sound when you turn on the machine?.Synchronous wheel screws are loose, the motor wire is broken, the motor is broken, the driver, voltage is abnormal, etc. Returning to the origin when starting the machine, and moving in the opposite direction.

#LIGHTBURN IMAGES ARE NOT ALIGNED DRIVER#

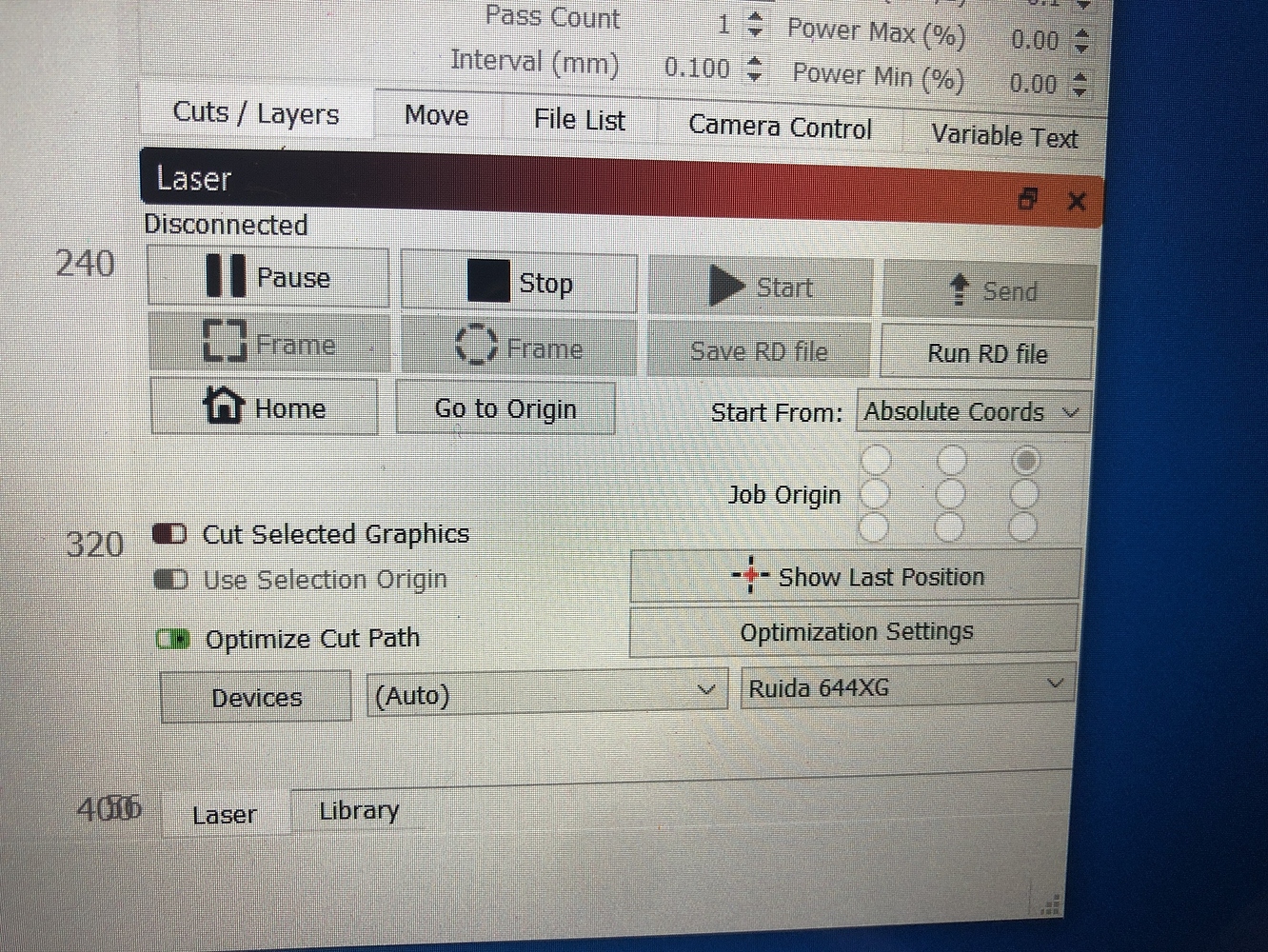

They are all determined according to the actual situation, from simple to deep.Ĭheck if the board driver is installed, whether the USB or network cable is plugged in, the USB or network cable is bad, the adapter board is broken, or the board is stuck. It may be because of the small power setting, the turned-down potentiometer, the biased light, the dirt lens, the reverse installed focusing lens, the focal length, the laser power, the attenuated laser tube power, the high water temperature, and the unstable voltage. Laser cutting effect is poor or can not cut through?.

0 kommentar(er)

0 kommentar(er)